project summary

The system we implemented in TROKOT automated the company’s business processes (BPA project). It significantly reduced the time between the acceptance of the order and the receipt of the finished product by the customer, as well as made this process transparent for both the buyer and the dealer.

CLIENT'S TASK

This example of business automation in our portfolio will be about the TROKOT company, which kindly allowed to mention its name in our portfolio and tell about the milestones of the work.

The business of the company is connected with production and sale of frame sun shades for car windows, as well as other car accessories. Initially our task was to automate interaction with the company's dealer network in Russia in order to simplify order management and improve dealer feedback with the manufacturer.

WORK DURATION, TASK MODIFICATION

We began working on the project in 2014. The client accepted our arguments and the list of tasks for automation, especially since the variant we proposed did not significantly increase in overall costs. Development and implementation of the project continued until the end of 2015. After that we switched to the project support mode. In general, the process lasted for about 2 years.

AUTOMATION ELEMENTS

During the work on the project we developed and implemented a full-fledged cloud ERP-system, covering all business processes of the company - production, finance, dealer network, etc.

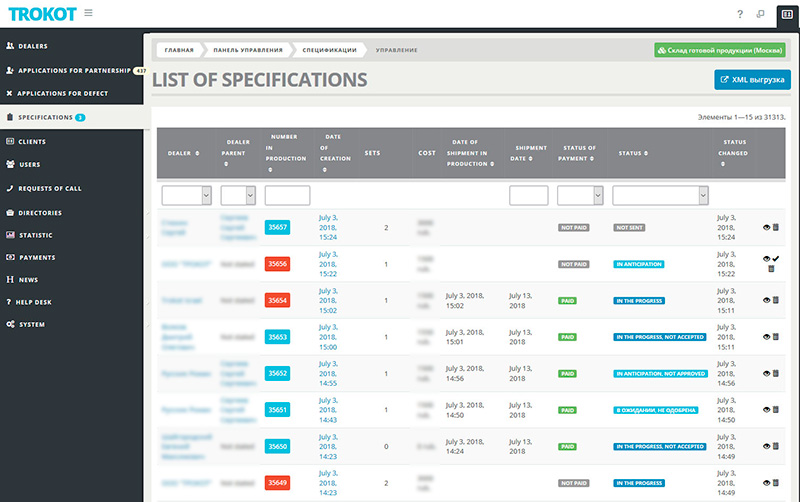

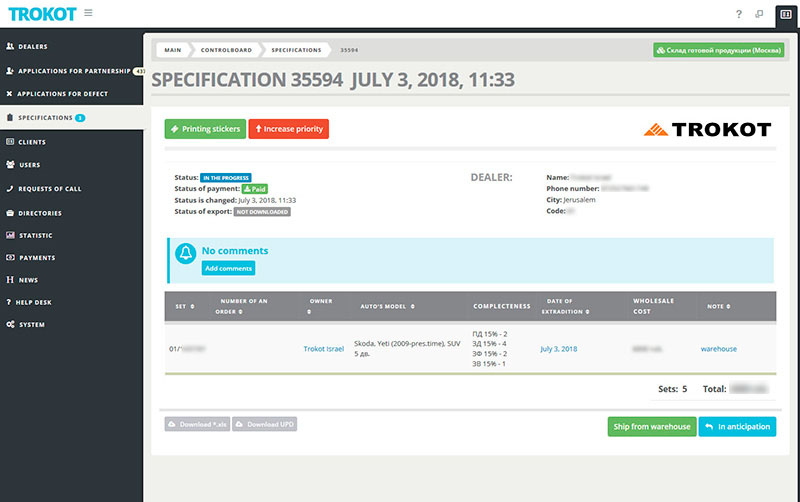

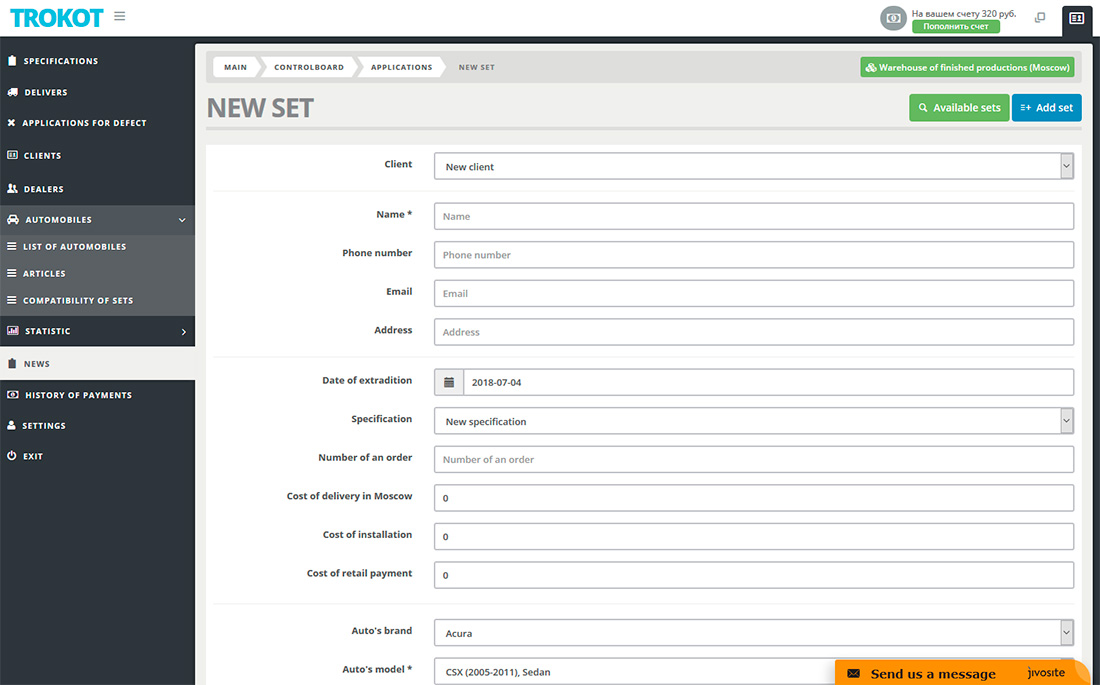

- Every dealer on the territory of Russia and in the CIS countries got a personal User Account, through which he could quickly forward the orders received to the central office, maintain records and track orders when they are ready.

- The procedure for collecting and calculating orders was significantly simplified. The transfer of orders to the production site was speeded up. The possibility of losing an order, distorting its parameters, etc. was completely excluded.

- We implemented the capability to track whether any order is ready at all stages of the production process and during sending it to the customer, sending notifications.

- A clear and effective system for handling complaints was formed.

- The system of warehouse accounting and storage was simplified. A reference database was created for all materials and components used, indicating storage locations in the warehouse.

- A barcode accounting system with a feature to print labels and stickers for finished products was developed and implemented.

- Financial management capabilities were significantly expanded. The company's management receives current information regarding movement of funds within the system at any time.

- The system of business management was automated. The management monitors current information on sales statistics, taking into account brands and models of cars, highlighting the top and outsiders in sales.

- We integrated the system with 1C, which significantly simplified preparation of accounting and tax reporting. It is possible to interact with third-party CRM systems, as well as to upload information about goods for online stores.

The above mentioned tasks are far from being a full list of capabilities of our product.

IMPLEMENTATION RESULTS

The system we implemented in TROKOT automated the company’s business processes. It significantly reduced the time between the acceptance of the order and the receipt of the finished product by the customer, as well as made this process transparent for both the buyer and the dealer. This did not take long to affect the company's profits and boost consumer confidence.

Simplification and acceleration of connections between individual departments made it possible to improve internal logistics, to reduce non-production costs, and to increase production efficiency. The company's management receives the following information in real time:

- Regarding every of 2000+ persons, using the system.

- Regarding all resources and financial flows.

- Regarding all orders and how they are fulfilled.

- Regarding every of 800+ dealers and their sales activity.

The time required to manufacture a unit of goods was reduced three times. The interval between receiving an order and delivering the finished product to the customer was reduced five times. The automation system turned out to be so effective that it allowed TROKOT to cross the borders of Russia and to expand its business activities to a number of CIS countries and far abroad.